Experimental Study of Fluid Flow Losses at Several Turning Angles

DOI:

https://doi.org/10.59535/faase.v2i1.238Keywords:

Fluid Flow, Turns, Flow DischargeAbstract

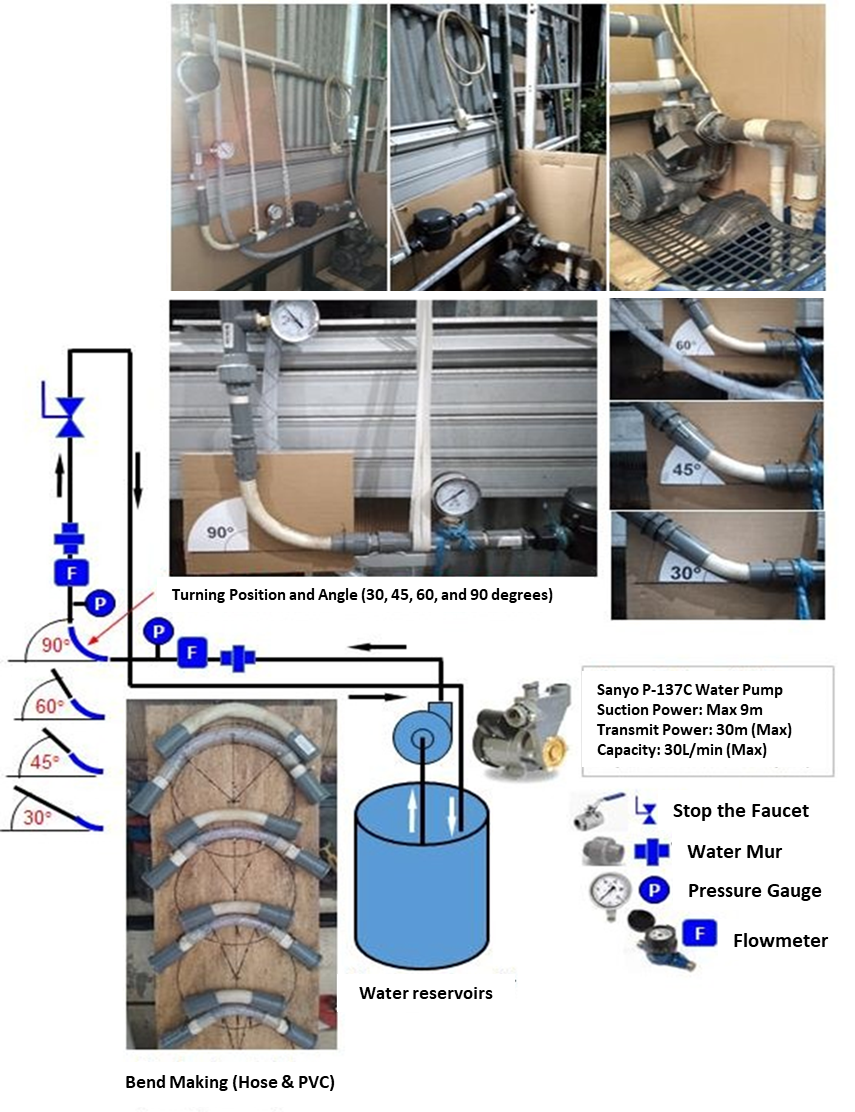

This research, entitled Experimental Study of Fluid Flow Losses at Turns 30°, 45°, 60° and 90°, is a review of fluid (water) flow in closed channels. Fluid (water) flow in opened and closed channels is influenced by the condition of the container in which the fluid flows. One form of this influence is the occurrence of a condition which is generally known as flow loss. This condition is certainly undesirable because it will cause problems, technically the manifestation is a decrease in pressure including the speed of fluid flow. To find out the real conditions of flow losses, it is necessary to carry out research stages. The research stages were carried out in the form of system design, measurement, testing and data analysis. The system is designed with a pump device, where the fluid is pumped from a holding container, then flows into the installation area or closed channel which is made using ½" PVC pipe and is equipped with a Pressure Gauge measuring instrument to measure pressure and a Flow meter to measure flow discharge, placing bends. with angles of 30, 45, 60 and 90 degrees. Indication of loss is indicated by a decrease in pressure measured at the pressure gate, while indication of a decrease in flow velocity is calculated using an equation with the flow input variable measured from the flow meter.

Downloads

References

C. R. Guerra-Tamez, M. C. Dávila-Aguirre, J. N. Barragán Codina, and P. Guerra Rodríguez, ‘Analysis of the Elements of the Theory of Flow and Perceived Value and Their Influence in Craft Beer Consumer Loyalty’, Journal of International Food & Agribusiness Marketing, pp. 1–31, 2020.

A. Arumugam, H. Kibrom, M. Gebreamlak, M. Teame, and M. Mengstu, ‘Comparative Analysis and Validation of Selected Explicit Equation Models for Determination of Darcy Friction Factor to Estimate Major Head Loss for a Pressurized Flow System’, Science & Technology Asia, pp. 216–235, Sep. 2022, Accessed: Mar. 12, 2024. [Online]. Available: https://ph02.tci-thaijo.org/index.php/SciTechAsia/article/view/241771

N. Ayuba, R. de Borba Buhler, L. S. da Silva, and T. J. Lopes, ‘Application of density-viscosity in predicting oil-water flow profile in horizontal pipe’, Exp. Comput. Multiph. Flow, vol. 4, no. 1, pp. 52–70, Mar. 2022, doi: 10.1007/s42757-020-0070-6.

T. Ganat, ‘Experimental investigation of viscous oil–water–sand flow in horizontal pipes: Flow patterns and pressure gradient’, Petroleum, Sep. 2023, doi: 10.1016/j.petlm.2023.09.005.

E. Liu, X. Wang, W. Zhao, Z. Su, and Q. Chen, ‘Analysis and Research on Pipeline Vibration of a Natural Gas Compressor Station and Vibration Reduction Measures’, Energy Fuels, vol. 35, no. 1, pp. 479–492, Jan. 2021, doi: 10.1021/acs.energyfuels.0c03663.

D. Zaman, M. K. Tiwari, A. K. Gupta, and D. Sen, ‘A review of leakage detection strategies for pressurised pipeline in steady-state’, Engineering Failure Analysis, vol. 109, p. 104264, Jan. 2020, doi: 10.1016/j.engfailanal.2019.104264.

G. Arun, S. P. Kumaresh Babu, S. Natarajan, and N. Kulasekharan, ‘Study of flow behaviour in sharp and mitred pipe bends’, Materials Today: Proceedings, vol. 27, pp. 2101–2108, Jan. 2020, doi: 10.1016/j.matpr.2019.09.076.

J. Park, T. Luong, and H. Moon, ‘Development of a Wheel-Type In-Pipe Robot Using Continuously Variable Transmission Mechanisms for Pipeline Inspection’, Biomimetics, vol. 9, no. 2, Art. no. 2, Feb. 2024, doi: 10.3390/biomimetics9020113.

X. Li, W. Li, J. Shi, Q. Li, and S. Wang, ‘Pipelines vibration analysis and control based on clamps’ locations optimization of multi-pump system’, Chinese Journal of Aeronautics, vol. 35, no. 6, pp. 352–366, Jun. 2022, doi: 10.1016/j.cja.2021.04.010.

J. Shi, A. Hu, F. Yu, Y. Cui, R. Yang, and J. Zheng, ‘Finite element analysis of high-density polyethylene pipe in pipe gallery of nuclear power plants’, Nuclear Engineering and Technology, vol. 53, no. 3, pp. 1004–1012, Mar. 2021, doi: 10.1016/j.net.2020.08.019.

C. A. M. Ávila, F.-J. Sánchez-Romero, P. A. López-Jiménez, and M. Pérez-Sánchez, ‘Leakage Management and Pipe System Efficiency. Its Influence in the Improvement of the Efficiency Indexes’, Water, vol. 13, no. 14, Art. no. 14, Jan. 2021, doi: 10.3390/w13141909.

A. I. Putri and M. Arisalwadi, ‘Analysis of The Influence Between Turbidity Value on Total Suspended Solid (TSS) Value At The River Water Surface In Kutai Kartanegara’, Frontier Advances in Applied Science and Engineering, vol. 1, no. 1, Art. no. 1, Oct. 2023, doi: 10.59535/faase.v1i1.129.

C. Yang et al., ‘Cross-validation enhanced digital twin driven fault diagnosis methodology for minor faults of subsea production control system’, Mechanical Systems and Signal Processing, vol. 204, p. 110813, Dec. 2023, doi: 10.1016/j.ymssp.2023.110813.

W. Wang, H. Sun, J. Guo, L. Lao, S. Wu, and J. Zhang, ‘Experimental study on water pipeline leak using In-Pipe acoustic signal analysis and artificial neural network prediction’, Measurement, vol. 186, p. 110094, Dec. 2021, doi: 10.1016/j.measurement.2021.110094.

Y. Yue, Y. Li, and X. Zuo, ‘Optimization of subsea production control system layout considering hydraulic fluid pressure loss’, Ocean Engineering, vol. 288, p. 116047, Nov. 2023, doi: 10.1016/j.oceaneng.2023.116047.

G. Du et al., ‘Improving thermal and hydraulic performances through artificial neural networks: An optimization approach for Tesla valve geometrical parameters’, Case Studies in Thermal Engineering, vol. 52, p. 103670, Dec. 2023, doi: 10.1016/j.csite.2023.103670.

A. A. A. E. Elmenshawy, I. Alomar, A. Arshad, and A. Medvedevs, ‘Computational Fluid Dynamics Analysis of Flow Characteristics and Heat Transfer Variabilities in Multiple Turbine Blade Cooling Channels’, Transport and Telecommunication Journal, vol. 25, no. 1, pp. 77–96, Feb. 2024, Accessed: Mar. 12, 2024. [Online]. Available: https://sciendo.com/article/10.2478/ttj-2024-0008

M. Arun, I. Rajendran, and S. Suresh, ‘Enhancing heat transfer efficiency and energy improvement through novel biosynthesized aqua-based silver nanofluid from leaf extract in a helical double pipe heat exchanger: a comprehensive investigation’, J Therm Anal Calorim, Jan. 2024, doi: 10.1007/s10973-023-12863-1.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Daud Orba Topayung, Paul M. Rumagit, Toban Tiku Pairunan, Tammy T.V. Pangow, Adolf Tonny Rasuh

This work is licensed under a Creative Commons Attribution 4.0 International License.

By submitting a manuscript to Frontier Advances in Applied Science and Engineering (FAASE), the author(s) agree to the following terms:

-

Copyright: The author(s) retain copyright to their work, granting Frontier Advances in Applied Science and Engineering (FAASE) the right to publish it. Articles are licensed under a Creative Commons Attribution 4.0 International License (CC BY).

-

License Grant: The CC BY license allows others to share and adapt the work for any purpose, even commercially, provided proper attribution is given to the original author(s) and the source, a link to the Creative Commons license is provided, and any changes made are indicated.

-

Author's Rights: Authors are allowed to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work, with proper acknowledgment of its initial publication in Frontier Advances in Applied Science and Engineering (FAASE).

-

Permissions: Reproduction, posting, transmission, or other distribution or use of the final published article, in whole or in part, requires prior written permission from Frontier Advances in Applied Science and Engineering (FAASE) and the respective author(s).

-

Attribution: Proper attribution must be given to the original author(s) and the source, indicating that the work was originally published in Frontier Advances in Applied Science and Engineering (FAASE) with a link to the published article.

-

No Warranty: The journal and its editorial team make no representations or warranties regarding the accuracy, completeness, or fitness for a particular purpose of the published work.

-

Dispute Resolution: Any disputes arising from the use of the licensed material shall be governed by the laws of [Jurisdiction] without regard to conflicts of law principles.

By submitting a manuscript to FAASE, the author(s) agree to abide by these license terms and grant the necessary rights to Frontier Advances in Applied Science and Engineering (FAASE) for the publication and dissemination of the submitted work.